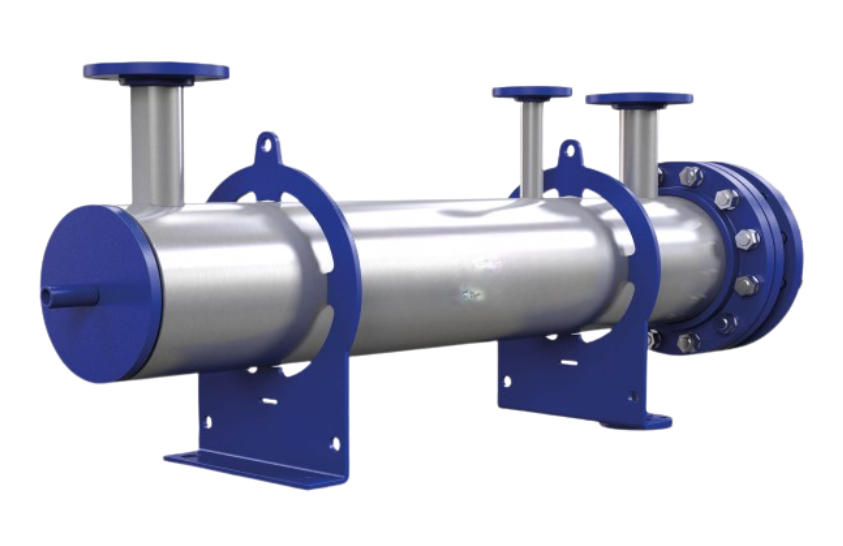

Service & Cleaning of Heat Exchangers

Performance audit, servicing and cleaning

AUTHORIZED SERVICE FOR ALFA LAVAL AND OTHER HEAT EXCHANGER BRANDS

We extend the operational lifespan of your equipment and reduce the risk of failures in heat exchangers

With regular cleaning and maintenance, we can significantly reduce the risk of failures, lower operating costs, and maintain high heat-exchanger performance. We offer warranty, post-warranty, and scheduled servicing for Alfa Laval, SWEP, GEA, Cetetherm and other heat-exchanger manufacturers. We minimize downtime through fast delivery of genuine spare parts, expert on-site intervention, and ongoing service support.

Guaranteed Professional Service

On-site Service

Service carried out on-site or at our service center. We always choose the most effective solution.

Fast Intervention and Repair

We handle breakdowns and urgent operational outages without unnecessary delays.

In-house Parts Manufacturing

We manufacture connection fittings and metal components in-house, ensuring fast, delay-free repairs.

What Our Professional

Heat Exchanger Service Includes

-

Performance Audit

-

Cleaning

-

Repairs and Refurbishment

-

Performance Upgrade

- Operational condition diagnostics of the heat exchanger

- Measurement of pressure drops, flow rates and temperatures

- Identification of the causes of heat exchanger performance loss

- Inspection report with recommendations for improving efficiency

- Complete disassembly, cleaning and reassembly

- Mechanical cleaning of the heat exchanger and its individual components

- Chemical cleaning of heat exchanger plates and bodies using CIP units (removal of scale, organic and inorganic deposits)

- Restoration of gaskets and joints

- Environmentally responsible disposal of waste materials

- Overhaul of plate and shell-and-tube heat exchangers

- Replacement of older heat exchanger types with new units

- Replacement of heat exchanger plates and bodies

- Complete regasketing

- Repair of mechanically damaged components

- Replacement of mounting and connection components (bolts, frames, brackets, insulation)

- Proposed modification of the heat exchanger configuration

- Technical adaptation for new operating conditions

- Optimization of media flow distribution for improved heat transfer

Service Center

The scope of the heat exchanger service, including the total price, is always agreed upon and confirmed in advance, ensuring full control over the service and its costs.

In our modern service center, we restore heat exchangers to full performance, tightness and reliability. We address fouled plates, deposits, leaks, hidden damage, upgrades and modernization.

Chemical bath cleaning gently removes both organic and mineral deposits, thoroughly cleaning even the internal structure of the heat-exchanger plates.

UV Plate Inspection reveals hidden cracks or damage that are not visible to the eye.

Most Common Questions

About Heat Exchanger Servicing

How often does a heat exchanger need to be cleaned or inspected?

The usual service interval is 1–3 years, but it depends on:

- the type of medium (hard water requires shorter intervals),

- operating load,

- temperatures,

- the presence of oils and contaminants,

- the heat exchanger manufacturer.

In industrial operations, food processing, or systems using hard water, annual servicing is recommended. For less demanding applications a 2–3 year interval is usually sufficient.

How do I know if my heat exchanger is fouled or losing performance?

A clogged heat exchanger can be identified by several warning signs:

- a higher temperature difference between inlet and outlet,

- reduced flow or increased pressure drop,

- longer heating times or slower system performance,

- higher energy consumption,

- vibrations, noise or irregular operation.

These issues occur due to deposits (scale, sludge, oil layers) that reduce heat transfer efficiency.

Is mechanical cleaning or chemical cleaning (CIP) the better option?

Mechanical cleaning is suitable for heavy deposits, hard scaling and fouling on plates or tubes, but it usually requires partial disassembly of the unit.

Chemical cleaning (CIP) is ideal for limescale, corrosion and organic buildup. It is performed without dismantling and is time-efficient.

In practice, both methods are often combined: CIP first, followed by gentle mechanical finishing.

Does the heat exchanger need to be disassembled for servicing, or can it be cleaned without dismantling it?

Disassembly is required only when:

- the heat exchanger is heavily corroded,

- nozzles or deep channels are clogged,

- gaskets or damaged plates need to be replaced,

- there is suspicion of leaks or mechanical wear.

How much does heat exchanger cleaning or servicing cost?

The service price usually depends on:

- the size of the heat exchanger,

- the type of cleaning required (mechanical / CIP),

- whether gaskets, plates or other components need to be replaced

- the distance and time required for a technician to come on-site.

You can find indicative rates and service billing procedures in our price list.