APTEC PRODUCTION S.R.O.

Your reliable partner

for engineering and technical assemblies

EXCHANGERS IN STOCK

CNC MACHINES

PRODUCTION AREA

Market demands drive us towards greater precision and better results

- 2018

- 2019

- 2020

- 2021

- 2022

- 2023

- 2024

- 2025

We start with a clear vision: to manufacture and assemble heat exchangers and heat exchanger stations that increase energy efficiency and operational reliability across Europe. We are becoming an official distributor of the Alfa Laval.

We are building our own service facilities. We now support customers not only with configuration and production, but also with regular servicing of heat exchangers, either directly on site or at our service centre.

Our need for precisely manufactured components led us to expand our production with high-precision CNC Machining and metal surface finishing. A new hall is being built and we are launching CNC production at full capacity.

We are adding our own transport. CNC parts and heat exchangers are dispatched safely to our customers directly from production.

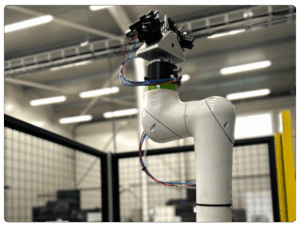

New robotic workstations. Our products are now even more precise and reliable.

With growth comes responsibility towards our environment. A photovoltaic power plant is being built on the roofs of our halls, helping to cover part of our energy consumption and reduce the carbon footprint of our production.

A strategic merger with WOOZ CNC. Demand for complex parts is growing faster than capacity, and we are therefore acquiring a majority stake in WOOZ CNC.

We are expanding our premises with an additional production hall. The new hall will provide greater painting capacity and new modern machinery.

Verified quality

Our production stands behind the projects of leading industrial companies

Precizion

without limits

More than 90%

EXPORT TO EUROPE AND OVERSEAS

Long-term trust from our clients