Gasketed Plate Heat Exchangers

Suitable for district heating, heating systems, cooling applications, pasteurization and heat recovery

EASY CAPACITY ADJUSTMENT AT ANY TIME TO MATCH YOUR OPERATING CONDITIONS

Heat exchangers engineered for energy-efficient operation without unnecessary downtime

Professional custom heat exchanger design

for any application

We are an official distributor of Alfa Laval, the global leader in heat transfer. We handle the complete technical design of your plate heat exchanger — from selecting the right type, plate count, and dimensions to installation, service and operator training. To deliver a fully customized solution down to the last detail, we manufacture supports, flanges, fittings and other components directly in our own CNC production.

- Design

- Installation

- Inbetriebnahme

- Individual selection of the heat-exchanger type based on your specific operation and media

- Professional calculation and precise determination of the heat exchanger performance

- Optimized design of the plate count and plate size

- Selection of suitable materials and gaskets with respect to service life and media

- Design of optimal flow rates and configurations for maximum system efficiency

- Precise assembly of the heat exchanger according to the approved design

- Quality and leak testing

- Preparation of connection elements (flanges, threaded joints, etc.)

- Delivery to the installation site

- Professional installation and commissioning of the plate heat exchanger

- Verification of operating parameters and flow values

- Practical operator training

- Handover of the complete technical documentation

- Scheduling the first service inspection

One investment. Endless configurations.

Save money and energy.

Technology designed for low operating costs and long service life

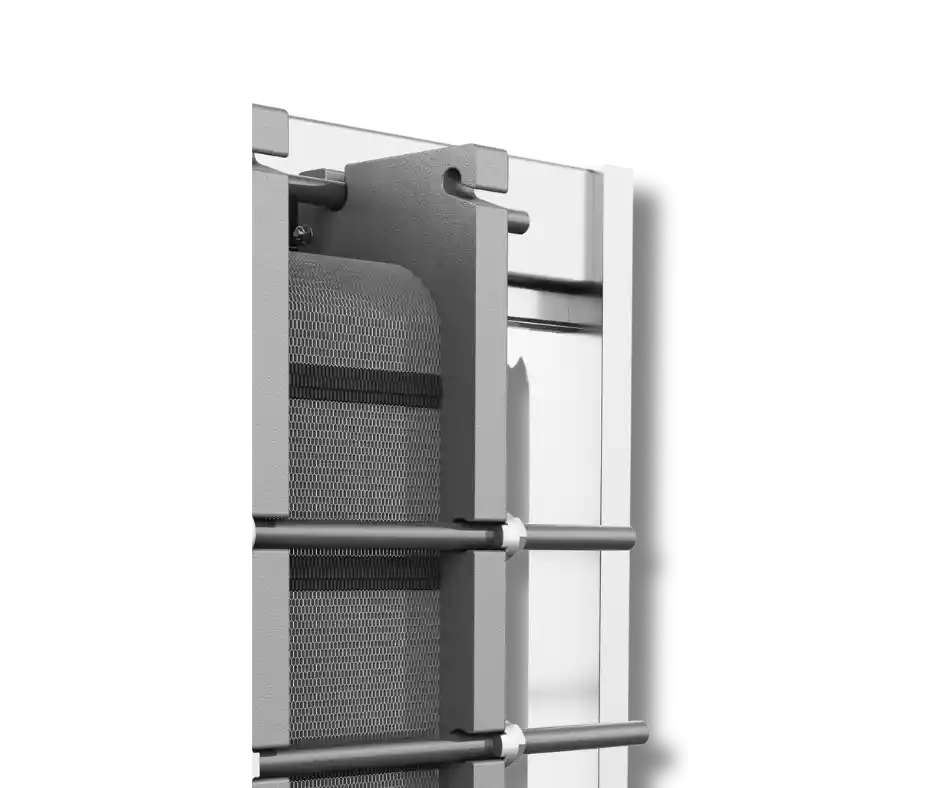

Design

The sturdy, serviceable frame provides quick access to the plates, easy maintenance, and flexible reconfiguration to match your operational needs.

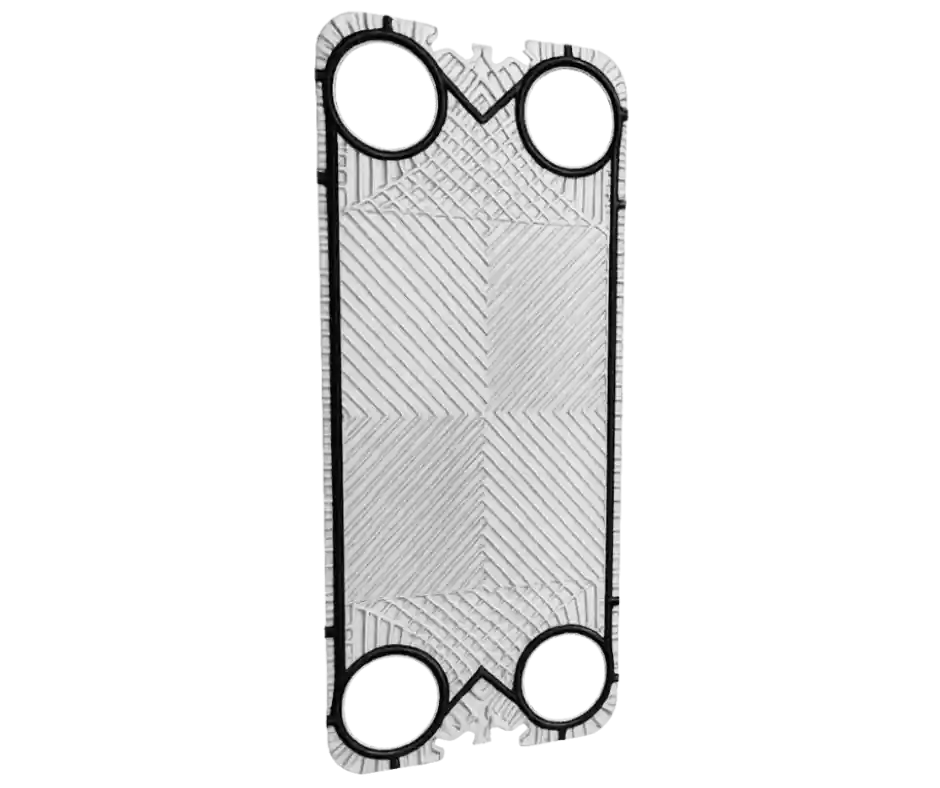

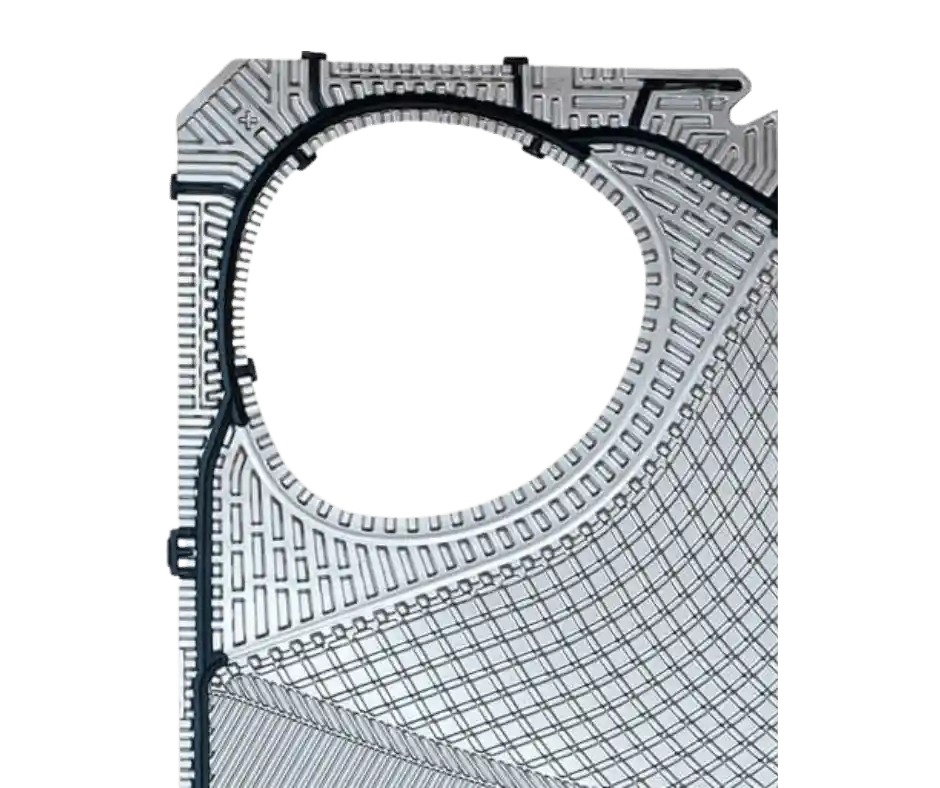

Plates

Thermally optimized plate profiles ensure efficient heat transfer, reliable operation, and reduced energy consumption.

Gaskets

The durable gasket is designed for easy replacement, long service life, and maximum sealing performance even under high load conditions.

Gasketed plate heat exchangers in practice

- Heat exchange stations for apartment buildings and industrial facilities

- Pasteurization and cooling in the food industry

- Liquid heating

- Cooling of oils and industrial machinery

- Heating in swimming pools and wellness centers

- Wastewater heat recovery

- Temperature control in pharmaceutical production

- Industrial cooling

- Industrial air-conditioning and cooling systems